Collaborator

Zach Hilt,

BioActive Devices Lab

Dev Team

Anton Bakerjian

Ian McHone

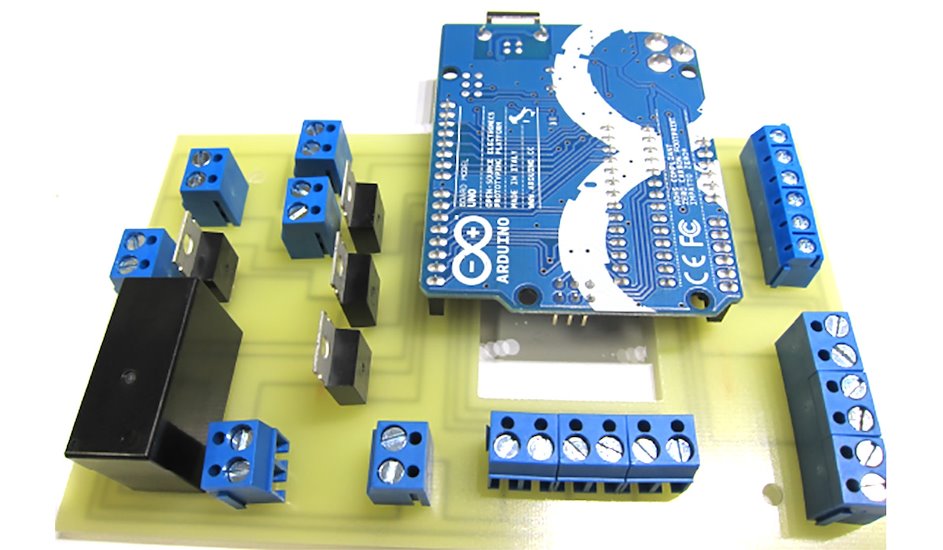

Project BlackBox brings together DIY and open source methodologies of software/hardware development with the field of material science. The goal of this work is to create the software and hardware tools that will allow designers to program and create responsive surfaces using smart materials. The initial phase of this work is focused on the programming and production of Shape-Memory Polymer, by creating a custom curing machine.The first step in this process involved two parallel strands of research into the methods of creating shape memory polymer. One strand was a hands-on, in depth look at how polymer is produced within a material science laboratory, and the second looked more generally at how polymer was created in a variety of scales and contexts. The latter revealed that production within this field occurs at 2 very distinct scales: the material science laboratory and the material factory. The material science lab is focused on developing new materials via small samples and the factories are focused on producing those materials at a very large scale. Typically the labs develop materials without any specific function in mind, and this distinct separation opens up the potential for a third scale in the overall scope: the material prototype. By creating a machine that can create material prototypes it allows designers to create material behaviours in the same way that they can create behaviours in software. This research represents a first step in this direction and creates interesting opportunities at the intersection of fabrication and programming.

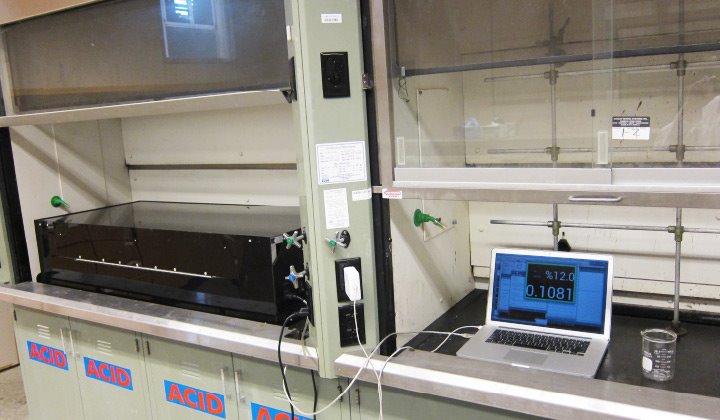

The system created uses high intensity UV lights mounted to a linear actuator to cure larger sheets of material within a lab setting.